Let’s Start Work

Together

Please feel free to contact us. We will get back to you with 1-2 business days. Or just call us now.

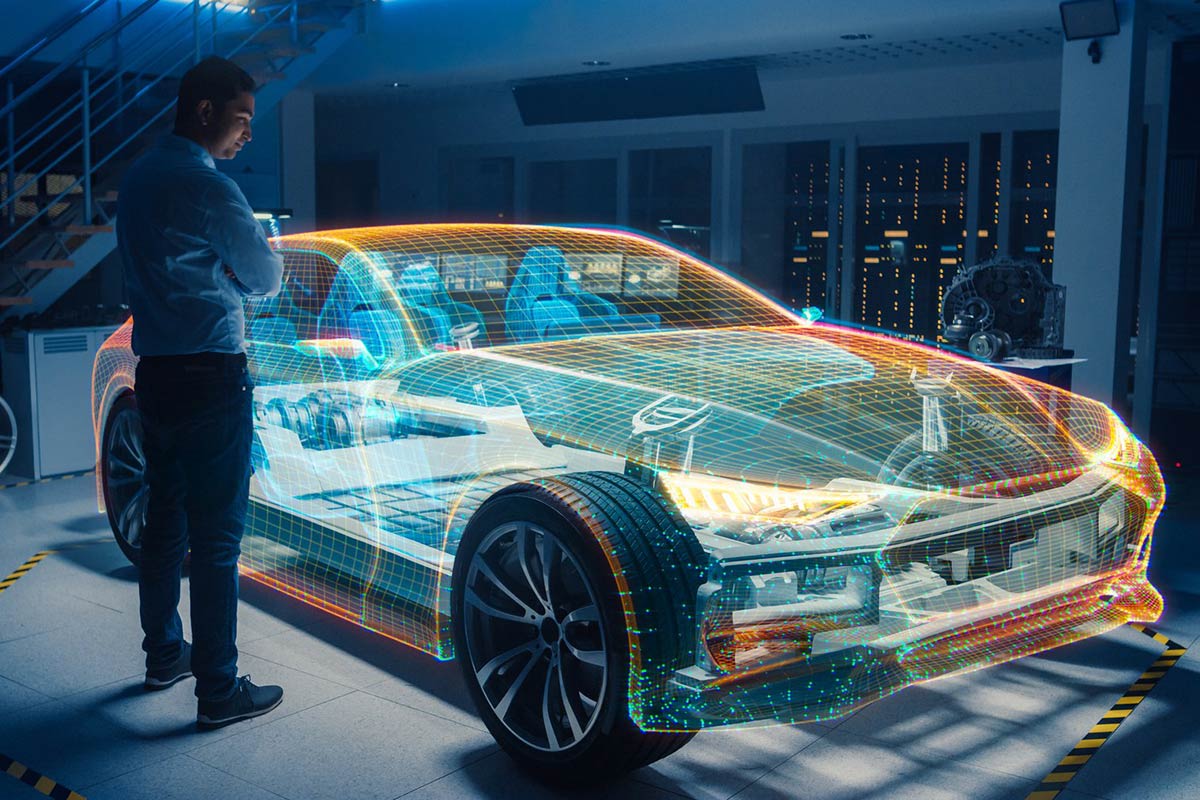

Our automation solutions focus on intelligent process automation and data-driven decision-making to significantly enhance operational efficiency, productivity, and process consistency. By integrating advanced technologies such as predictive maintenance, we proactively identify potential issues to minimize downtime and reduce maintenance costs.

With a strong emphasis on safety, regulatory compliance, and quality control, we help our clients optimize production processes, reduce operational risks, and extend asset lifecycles. These smart automation strategies empower businesses to drive sustainable growth, improve ROI, and stay competitive in rapidly evolving markets.

We are providing

We implement advance automation systems designed to streamline our clients' operations, optimize production processes, and ensure product consistency at every stage. By integrating cutting-edge technology, we reduce manual intervention, minimize errors, and enhance overall efficiency - leading to lower costs and faster turnaround times. Our automation solutions are tailored to meet the unique needs of our clients' business, increasing productivity and scalability while maintaining the highest standards of quality control.

By integrating advanced data analytics and AI-powered solutions, we enable businesses to gain actionable insights, enhance operational control, and make data-driven decisions with confidence. Our AI-driven analytics help identify patterns, predict trends, and uncover hidden opportunities, empowering organizations to streamline processes, optimize performance, and achieve measurable growth. With real-time data monitoring and predictive analytics, companies can respond swiftly to market changes, improve customer engagement, and drive innovation across all areas of their operations.

Leverage our advanced predictive maintenance solutions to proactively identify and address potential equipment issues before they escalate into costly failures. Our system uses real-time data analytics, machine learning and IOT sensors to continuously monitor asset performance, allowing our clients to detect early warning signs and schedule maintenance precisely when needed. This proactive approach not only minimizes unplanned downtime and reduces maintenance cost but also extends the lifecycle of any valuable asset, achieving greater operational efficiency, and reliability.

Our automation solutions are designed with a strong emphasis on safety features and strict regulatory compliance, ensuring safe, efficient, and highly productive working environment. We integrate advance safety mechanisms that minimize risk, protect personnel, and safeguard equipment, meeting and often exceeding industry standards and government regulations. By prioritizing compliance with safety certifications and regulatory frameworks relevant to any industry, our automation solutions help our clients not only enhance workplace safety but also streamline operations and boosts overall productivity.